Apollo, 150w Metal Halide, wide flood beam, IP65

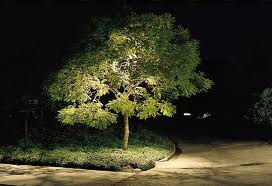

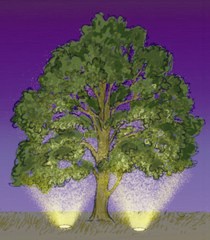

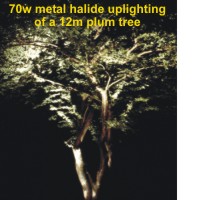

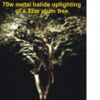

The code E94150W is a surface-mount wide beam flood light with a 60 degree beam angle primarily designed for energy-saving up lighting of trees or building facades. Apollo has an adjustable stirrup bracket for mounting on walls or an optional ground spike. The lens has "through-flow" slots to allow water to flow off the lens even if pointed directly upward or fitted with a glare shield. It uses a 150 watt single-ended metal halide lamp and polished reflector to project a 60 degree symmetric circular beam for up lighting larger trees: the central 60 degree beam is ideal for up lighting from beneath and is complemented by peripheral light spread for coverage of canopies. Where the shape of the tree falls within a 40-60 degree arc, use E94150W to cover up to 30m high, subject to density & colour of canopy & structure: perception of brightness varies between different people. If the tree has a wider spread, especially over 10m, use 1 or more E94150W 60 degree spotlights for a fuller effect. Use 70w models for smaller trees . Where the outer canopy is dense and the inner canopy & structure is more open, up light the central trunk & branches with one Apollo 36 degree spotlight and position other Apollo spotlights to illuminate the outer canopy. Look up through the tree you propose to light - if you can see up through the branches, then light will penetrate the canopy and structure as well. If not, use up lights to light the tree externally. Lighting large trees is a black art: test the position of up lights with a temporary wiring set-up before final installation. Lighting of trees with very open canopy may be brighter than desired - consider Apollo 35 35w metal halide spotlights or a range of LED floodlights as a lower power alternative. This advice is for general guidance and subject to branch & canopy structure and foliage density, colour & translucence.

Environmental impact

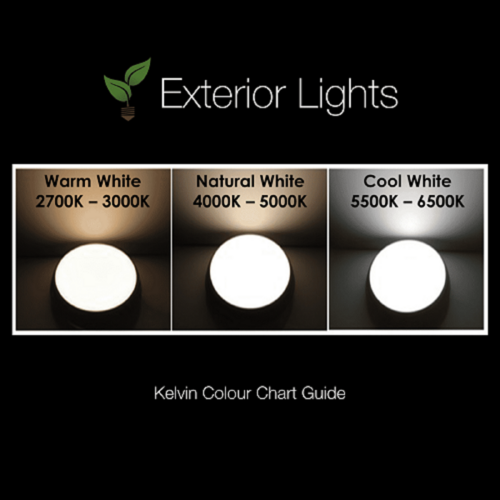

Care should be taken for the environment and local wildlife to maintain the ecological balance. Insects, bats, wildlife can all be affected by light pollution. The warmer colour spectrum of 2,700 Kelvins does not interfere with insects and general wildlife as much as the blue colour spectrum of light around 6,000 kelvins which can disrupt their normal night-time activity. This also applies to bats where an anti-glare light fitting works better as well as reducing the overall light pollution in the area. You must also be mindful of your neighbours and the effect your lighting can have on them and shining a flood light into their windows at night will cause them distress. Try to keep the light in a downward position and local to the area you want to illuminate and even if you want to illuminate tall trees it can be done in a sympathetic way by placing a ground buried or surface spike flood light directly under the trees to illuminate the canopy. Some light fittings also have an anti-glare shield fitted to reduce light pollution.

Lamp type

240v Installation - See Instructions & Data Sheets Tab

Stirrup bracket for mounting on walls or an optional ground spike. 20mm IP68 gland provided for connection to mains supply. HO7-RNF 3 core rubber cable recommended for connection to armoured supply cable via a separate weatherproof junction box or underground joint kit (not supplied).

Using a single RCD for large numbers of 240v fittings is not recommended due to the risk of nuisance tripping. We advise the use of separate RCD protection for each circuit and a maximum of 12 fittings per RCD. Where a garden lighting installation of more than 12 spike mount or recessed lights per circuit is proposed, we suggest the installation of 12v units with transformers, which results in a significantly higher fault tolerance and reliability in the total installation.

Specifications

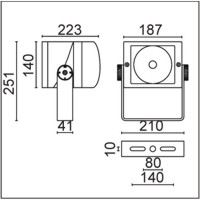

| Range | Apollo 150w E94150W |

|---|---|

| Adjustable | Yes |

| Beam Angle | 60° |

| Bulb Light Source Description | 1 x 35w GU8.5 |

| Bulb Type | G12 |

| Colour | Grey |

| Control Gear Used | built in gear |

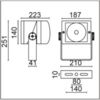

| Height | 140 |

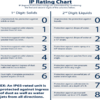

| IP Rating | IP65 |

| Materials | Aluminium |

| Voltage | 240v |

| Warranty | 2 Years |

| Watts | 150W |

| Width | 187 |

Downloads

-

E94150W_-_Ver1.0_-_31-08-2016.pdf

pdf, 360.32 KB

PRODUCT AFTERCARE

Although each of our light fittings come with a warranty, it is also important to take care for your product after installation. The outdoor environment can be harsh with very warm and hot conditions as well as extremely cold, wet, and windy conditions and more especially in coastal areas where the salt air is more concentrated causing corrosion. By neglecting to care for your product may void any warranties. Below is information on caring for the different type of products we sell.

COPPER, BRASS & BRONZE

Brass and Bronzes are families of copper-based alloys and mainly copper and zinc. Bronzes are mainly copper along with alloying elements such as tin, aluminium, silicon, or beryllium. Brass generally has a bright gold appearance dependent upon the percentage of copper yields, the higher the percentage the rosier the tone will be, and more zinc will make it appear silvery. Brass has higher malleability than bronze or zinc and is ideal for resisting corrosion including galvanic corrosion from saltwater. Copper products start off with a shiny orange appearance and once installed copper weathers naturally to a lovely blue-green colour or patina over time. In arid climates, the colour change is usually to a nut brown. The colour change is the result of surface oxidation caused mainly by moisture and corrosive elements in the atmosphere. Unlike rust oxidation, the copper patina is a protective barrier that retards further corrosion, to maintain copper’s long life. They are ideal for coastal areas and to keep them looking pristine we recommend cleaning copper surfaces periodically with a solution of salt and vinegar to remove any excess deposits. Simply dissolve salt in vinegar, then use a soft cloth to apply the liquid solution to the surface of the fitting then buff until you see the copper begin to shine. Rinse and dry. The ‘Brasso’ product is a metal polish designed to remove deposits from brass, copper, chrome, and stainless steel. WD 40 is also useful for cleaning brass too and wipe off with soapy water.

316L & 316 STAINLESS STEEL

The highest grade of Stainless Steel we use is 316L Marine Grade Stainless Steel which is a low carbon version of 316 Stainless Steel (which is why it has L after the 316). These grades of Stainless Steel are popular for use in Coastal areas due to the materials immunity from boundary carbide precipitation (sensitisation). However, 316 Stainless Steel contains more carbon and although is still corrosion resistant it does still need care to remove the deposits that build up on the surface or the corrosion will eventually start to build up on the surface. We sell more 316 than 316L products on this website. The elements of 316L and 316 Stainless Steel are Carbon, Manganese, Phosphorous, Sulphur, Silicon, Chromium, Nickel, Molybdenum, Nitrogen, and Iron. The only difference is that 316L has 0.03 max % of Carbon and 316 has 0.8 max % of carbon. To maintain the shiny clean surface of 316L and 316 Stainless Steel we recommend the use of Stainless-Steel cleaning products or a solution of lemon juice and baking powder and wiped off with soapy water.

304 STAINLESS STEEL

304 Stainless Steel is made up of Carbon, Manganese, Phosphorous, Sulphur, Silicon, Chromium, Nickel, Nitrogen, and Iron. There is no presence of Molybdenum the anti-corrosive element and this metal has a high carbon content too. Therefore, we would not recommend this metal used in coastal areas. Again, it can be cleaned with Stainless Steel cleaning products or a solution of lemon juice and baking powder and wiped off with soapy water. In addition, we would suggest using an anti-corrosive spray such as ACF-50 which forms a clear film onto the surface of the fittings and adds protection to the surface for up to six months. We sell this on our website. /product/corrosion-block-anti-corrosion-formula-946ml-bottle-with-trigger-spray

201 STAINLESS STEEL

201 Stainless Steel is made up of Carbon, Manganese, Phosphorous, Sulphur, Silicon, Chromium, Nickel, Nitrogen, and Iron. It contains half the nickel and more manganese and nitrogen than the other popular steels. It is also the least expensive of the steel metals we sell. This mid-range product is prone to corrosion such as salt water and not suitable for coastal areas. Again, it can be cleaned with Stainless Steel cleaning products or a solution of lemon juice and baking powder. In addition, we would suggest using an anti-corrosive spray such as ACF-50 which forms a clear film onto the surface of the fittings and adds protection to the surface for up to six months. We sell this on our website. /product/corrosion-block-anti-corrosion-formula-946ml-bottle-with-trigger-spray

TEAK WOOD

Our Teak lighting use timber from a sustainable source, organically oiled during production to enhance and protect the grain. The teak bollards for example are made from a natural raw material which reacts to temperature changes and will naturally release sap or may sweat inside the protective packaging. So, please don’t be alarmed if you notice this when you unpack the bollards from their packaging. Once installed, they will weather naturally in the garden, although further oil, stain or varnish treatments are recommended periodically to preserve the beauty of these products. This should also help prevent the build-up of mildew and drying out from the sun. Teak Sealer and Teak oil can be purchased from many timber and DIY stores. They are suitable for all areas including coastal areas.

ALUMINIUM

Many of our products are made from aluminium which is formed of aluminium oxide in an ore called bauxite. Alumina and bauxite are the two main raw materials in the aluminium making process. Aluminium is obtained by the electrolysis of alumina which extracts pure aluminium metal from alumina. Aluminium will not rust however it does suffer from oxidation and is prone to corrosion. We would not recommend Aluminium products in coastal areas. To maintain the surface of the product you can clean with a solution of vinegar and water and rinse with soapy water. Again, our ACF-50 anti-corrosive spray will provide a clear protective coating to the surface of the fittings and can offer up to six months protection. /product/corrosion-block-anti-corrosion-formula-946ml-bottle-with-trigger-spray

POWDER COATED FINISHES

Many of our coloured finished products have been powder coated onto aluminium. This is a technique to apply decorative and protective finishes to aluminium through a process that electrostatically charges the powder consisting of a mixture of finely milled resin and pigment, spraying it on to the aluminium surface as a baking process. Although they look effective, please bear in mind that the powder is a paint and in coastal areas the paint can peel and expose the aluminium to corrosion. Therefore, we would not recommend powder coated aluminium fittings in coastal areas. To clean the surface simply use soapy water and a soft cloth and do not use anything abrasive as this will damage the finish. Again, our ACF-50 anti-corrosive spray will provide a clear protective coating to the surface of the fittings and can offer up to six months protection. /product/corrosion-block-anti-corrosion-formula-946ml-bottle-with-trigger-spray

ANODISED PAINT FINISH

Anodised coloured paint finishes give a lustre shiny finish to the surface of aluminium fittings and this is done by dipping the aluminium component into an acid electrolyte bath and applying an electric current to the liquid using a cathode. This causes oxygen ions within the aluminium to be released, which then combine with the aluminium atoms on the surface of the component to create the anodic oxide finish. This process gives the metal surface a porous structure, which can then be coloured with dyes and sealed afterwards. The advantage of the anodised finish is that it is not applied on the surface of the metal, instead, it is integrated with the aluminium substrate, which means it does not peel or chip like paint. The beauty of anodising is that it does not come off and it should protect the aluminium depending upon the thickness for at least 5 years and therefore reduce corrosion occurring. If used in coastal areas, we would recommend they are cleaned regularly with soapy water. Again, our ACF-50 anti-corrosive spray will provide a clear protective coating to the surface of the fittings and can offer up to six months protection. /product/corrosion-block-anti-corrosion-formula-946ml-bottle-with-trigger-spray

POLYCARBONATE (PC) –PLASTIC

Polycarbonate is a durable thermoplastic material with high impact resistance. It is quite light in weight and used primarily for Amenity style light fittings. It is fine for use in all areas including the coast. It should be cleaned periodically with warm soapy water to remove any deposits that have accumulated over time.

FeCSI-Steel

The element Iron (Fe) used in conjunction with steel alloys is put together to produce a product that eliminates the need for painting, and which forms a stable rust-like appearance after several years’ exposure to the weather. This product is used in some of our bollards under our ‘Rustic Bollard’ Category. They are very heavy and robust fittings. The surface oxidation of weathering steel takes approximately six months. When first purchased some residue rust colour from the manufactured product may be visible and will wash away with the elements of the weather. Over time they will naturally give a rust effect appearance and you will be able to touch them without any rust residue staining. An example of this is shown on our website for the ‘Rusty Slot’ fitting. They are ideal for all areas including the coast.

GRANITE

Granite is a coarse-grained igneous rock composed mostly of quartz, alkali feldspar and plagioclase. It is a hard semi-porous rock which is resistant to heat and cold. Ideal for any area, however salt deposits in coastal areas will accumulate onto the surface of the rock so it is advisable to clean the surface with warm soapy water periodically. Do not use anything abrasive.

Delivery within 2 days

Delivery within 2 days